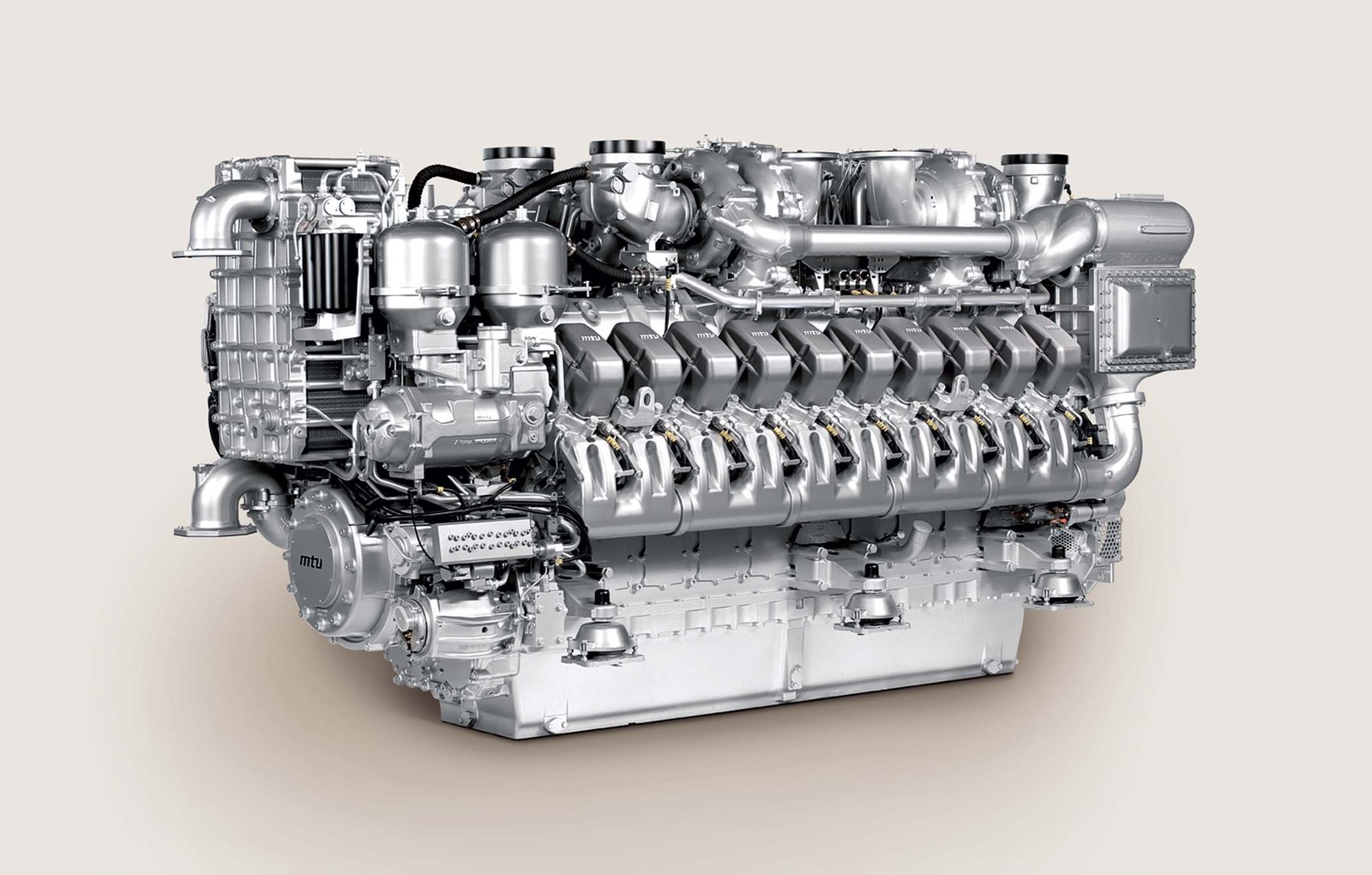

When you need premier performance for your vessel, MTU’s Series 4000 engines deliver. Available from 1000 – 4828 bhp, Series 4000 engines operate with the highest levels of efficiency and profitability with low fuel consumption and long service intervals. You’ll also experience less vessel downtime due to the innovative technology behind MTU engines which increases their reliability and safety.

Lifecycle Costs

Service Network

Reliability

Technology

Product Range

More than 20 years ago, in 1996 the first mtu Series 4000 marine engine was presented at SMM exhibition in Hamburg. Since then, the mtu Series 4000 is trusted in numerous applications. With more than 58,000 Series 4000 engines sold worldwide we gained experience from more than 345,000,000 operating hours which were directly fed into the development of the next generation of our marine workhorses.

This is just as true today, as it was in 1996 when we introduced the first high speed diesel engine with common rail fuel injection. Since 2016, we have the only high-speed diesel engine for hard workboat applications with a power output of up to 4300 kW (5780 hp).

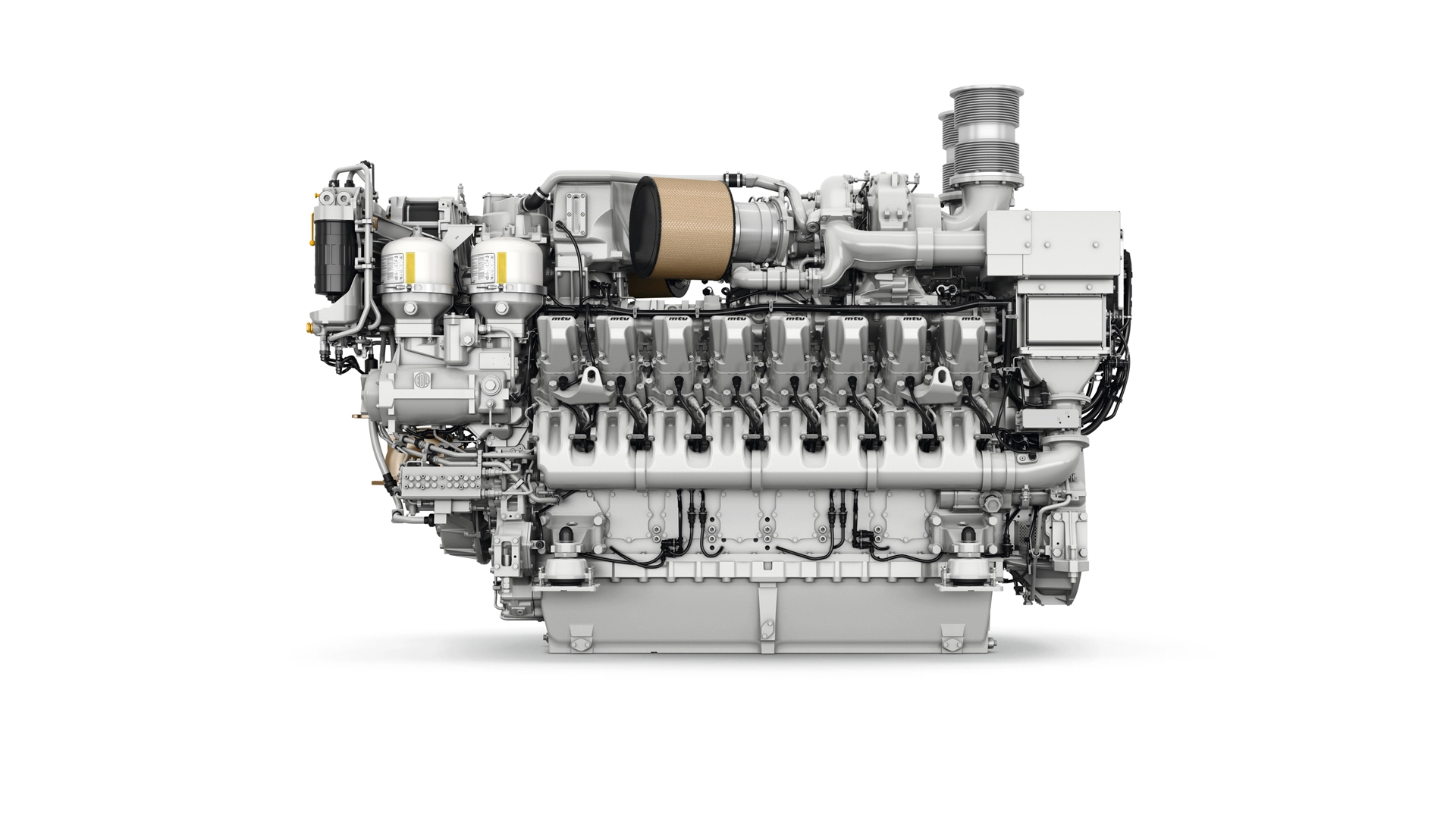

Series 4000 M05 for commercial marine applications is the latest marine engine of the powerful Series 4000 family. When designing the Series 4000 M05 we kept three topics always in our mind: Life-cycle- costs, perfomance and ease of maintenance. We used our legendary IRONMEN engines as a basis but finetuned it with high attention to detail to maximize durability, performance and efficiency. Some examples: we changed the alloy of the piston ring to reduce wear. We also relocated fuel filters to grant optimal servicability.

Additionally the air filters are now integrated in the outline of the engine which makes the Series 4000 M05 even more compact. We used advanced simulation of the combustion process to reduce particulate matter inside the engine which makes the need for an additional DPF redundant. Only SCR is needed to fulfill IMO III and EPA Tier 4 emissions regulations.

Electric starter motor 24V, 2 pole

Gear driven lube oil pump, switchable oil filter, centrifugal oil filter, lube oil heat exchanger, closed crankcase ventilation

Fuel delivery pump, duplex fuel filter with diverter valve, common rail fuel injection system with high-pressure pump, pressure accumulator and electronic fuel injection with cylinder cutout system, jacketed HP fuel lines, flame-proof hose lines, leak-off fuel monitoring, switchable pre-filter with water separator in conjunction with switchable additional secondary filter

Engine control and monitoring system (ADEC); engine interface module - EIM, engine mounted, expansion in ompliance with extended scope of monitoring

Separate high and low temperature cooling circuit (engine version for separate heat exchanger), gear driven coolant circulation pumps

Triple-walled, liquid-cooled, on-engine exhaust manifolds, 30° (upwards against horizontal) elbows discharge, exhaust bellow

Engine coolant temperature-controlled intercooler, turbocharging with 2 water-cooled turbochargers, on-engine seawater-resistant air filters, intake air silencer (16V/20V)

mtu NautIQ Core/ mtu NautIQ Master/ mtu NautIQ Foresight

| Models | BHP | RPM | Displacement |

|---|---|---|---|

| 8V 4000 M53R | 1000 | 1600 | 2331 |

| 8V 4000 M54R | 1000 | 1600 | 2331 |

| 8V 4000 M54 | 1200 | 1800 | 2331 |

| 8V 4000 M53 | 1234 | 1800 | 2331 |

| 8V 4000 M63 | 1341 | 1800 | 2331 |

| 12V 4000 M53R | 1529 | 1600 | 3491 |

| 12V 4000 M54 | 1600 | 1800 | 3491 |

| 12V 4000 M53 | 1851 | 1800 | 3491 |

| 12V 4000 M64 | 1875 | 1800 | 3491 |