20% fewer oil consumption than other competitive products.

Optimizes operation across the torque curve resulting in excellent low-end torque. Holset supercharger with integral wastegate offers low-speed response and dynamic performance.

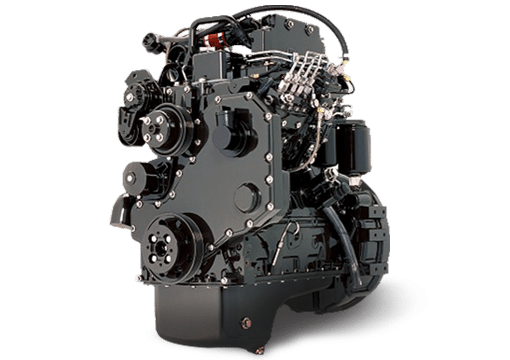

4B series engine contains up to 40% fewer parts than competitive engines in its class.This results in a better power-to-weight ration,a less chance of failure and lower repair cost.

Make the engine delivers superior performance and lower cost than competitive engines.

Optional assistant cold starter with improved 6KW starter and intake air heater.

Adopt advanced design to achieve higher horsepower and lower weight,horsepower per liter reached 24.9 Kw/L.

When Rio Tinto looked to improve life-to-overhaul of the Cummins engine powering its Komatsu WA1200-6 loaders, oil filtration efficiency emerged as the key. The first equipped with an engine-mounted Cummins Eliminator oil filtration system that replaced the engine’s standard remote-mounted four spin-on filters.

Cummins Technical Team analysis determined that the Eliminator system would give us a 20 percent increase in engine life based on fuel burn, leveraging reduced flow restriction and improved filtration efficiency. Eliminator is a natural fit in the WA1200,It sits right behind the service access panel so maintainability of the machine is significantly improved. Rio Tinto has also adopted the disposable Eliminator centrifuge cartridge, significantly reducing service complexity, cost and downtime.

Achieving the lowest possible fuel consumption is another key element of Rio Tinto’s technology roadmap to reduce life cycle costs. Another change that has occurred concurrently with the Eliminator installation is the fitment of dual 19 kg Prestolite starter motors, replacing the standard starter motors that weighed 35 kg. The key benefit is safety in that the lighter Prestolite units are far easier for a mechanic to replace.