Large capacity aftercoolers are supplied with three different configuration types, which are dependent on the rating used: Jacket Water Aftercooled (JWAC), One Pump Two Loop (1P2L), or Two Pump Two Loop (2P2L). This provides cooler, denser intake air for more complete combustion and reduced engine stresses for longer life and low exhaust emissions.

The JWAC aftercoolers share cooling water with the high temperature jacket water cooling system. There are no separate aftercooler connections that the customer needs to make. The 1P2L aftercoolers utilize coolant drawn from the jacket water system, but operate at a lower temperature than the jacket water, due to a separate, lower temperature thermostat. Two water pump employs separate impellers on a common shaft to deliver coolant to the two different systems. Similar to the 2P2L system, two different radiators are used to cool the engine jacket water and the aftercooler water. The 2P2L utilizes two completely separate water pumps. The engine jacket pump is engine mounted and is driven from the rear of the gear housing. The aftercooler water pump is customer selectable and can be provided mounted on the front of the gear cover. Cummins provides conventional water inlet and outlet connections for the jacket system. Aftercooler water pump inlet and aftercooler core outlet connections are provided for customer use and ease of plumbing on the aftercooler system.

Large capacity integral gear driven pump provides pressure lubrication to all bearings and provides supply for piston cooling. Cummins supplied large capacity oil pans are recommended for Prime and Continuous Power applications.

Pistons are dual Ni-resist, aluminum alloy, ground and shaped to compensate for thermal expansion which assures a precise fit at all normal operating temperatures. Oil cooled for rapid heat dissipation. Two compression rings and one oil ring. Utilizes offset piston pin for reduced susceptibility to liner cavitation.

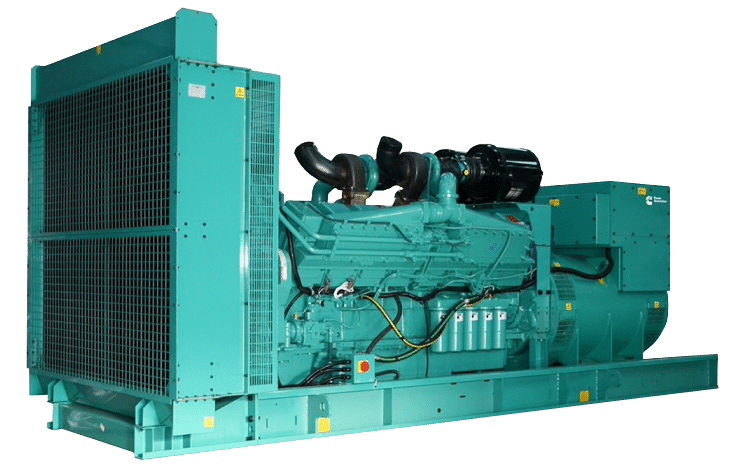

Controlled high performance QSK50 series power, this new series uses our state-of-the-art Quantum system to provide advanced engine manipulation and an enhanced electronic feature set. The configuration also includes new injectors, pistons, turbos, valve covers and a 2-pump, 2-loop Low Temperature Aftercooling (LTA) system to meet U.S. EPA Tier 2 mobile off-highway emission levels, and make the QSK50 one of the cleanest engines in its class.

High pressure fuel pump, Modular Common Rail fuel System (MCRS) and state of the art integrated electronic control system provide superior performance, efficiency and diagnostics. The electronic fuel pumps deliver up to 1600 bar injection pressure and eliminate mechanical linkage adjustments.The new MCRS utilizes an electric priming pump which is integrated with the off-engine stage-1 fuel filter head and is controlled and powered by the engine ECM. The stage-2 fuel filters are mounted on-engine.

CTT (Cummins Turbo Technologies) HX82/HX83/HE851 turbo-charging utilizes exhaust energy with greater efficiency for improved emissions and fuel consumption.

Each component has been specifically developed and rigorously tested for G-Drive products, ensuring high performance, durability and reliability.