Integral steel piston and the high-strength cylinder and crankshaft that can withstand 230 bar ultra-high burst pressure, harsh component test verification, higher engine strength, and excellent reliability.

Advanced Cummins XPI ultra-high pressure fuel injection system with injection pressure up to 2400 bar offers a minimum fuel consumption of 186g/kW·h, the engine is a perfect combination of emission and economy, optimized combustion chamber and high piston rings, advanced four-valve structure, low Cylinder head airflow swirl ratio, high injection pressure fuel system, near zero smoke.

Cutting-edge Cummins electronic control intelligent module consistently monitors the engine’s running state and precisely controls fuel injection, empowering the engine to “think”.

With advanced design, the engine gains maximal power per liter, which is up to 38.5 kW / liter. The three-stage filter ensures balanced particle dispersion, protects main components of the fuel system and maximizes engine life. Easy start-up at -15°C ambient temperature without any cold-start assistance systems. Start up at -30°C with auxiliary systems.

The mature intelligent electronic control technology improves the overall performance of the engine,electronic control system intelligently switches to operation modes according to the environment and operating conditions. It has self-diagnosis, alarm and remote monitoring functions.

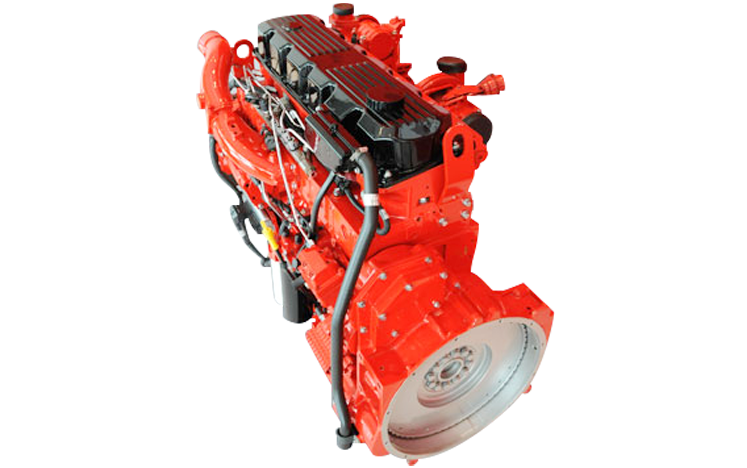

The QSZ13 engine was developed using Cummins unique in-house capability, adapting core technologies in electronics, fuel systems, turbo charging, filtration, and emissions. The QSZ13 engine has low derating thresholds for temperature and altitude, coupled with 50C ambient capable cooling system makes these engines top performers in the harshest conditions.

From loaders to excavators and cranes, Cummins engines can be found in almost every type of construction equipment imaginable. Products are supplied complete with cooling package and air cleaner kit for a complete power package. A Heavy duty air cleaner is offered as an option.

Advanced engine monitoring, diagnostics, protection and control, coupled with the XPI fuel system, capable of delivering extreme fuel injection pressures with multiple injection events, results in reduced emissions, improved fuel efficiency, lower noise and enhanced engine performance.

Cummins patented variable impactor breather design and coalescing filter removes emissions as required by regulations, with the added benefit of eliminating oil drips and mist while keeping the surroundings clean.

Fitted with a Power Generation Interface (PGI) to improve emissions, the widely accepted SAE J1939 industry standard CAN based communication network provides advanced engine protection, ensuring faster connectivity along with a superior fault finding capability.