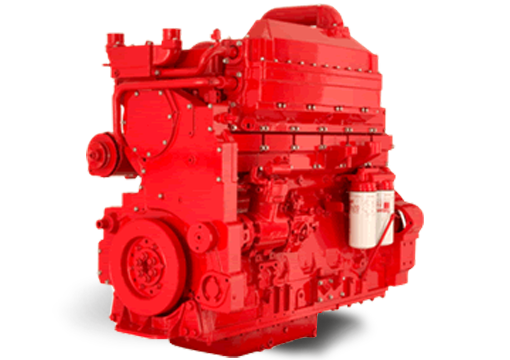

Power covers 450-890 hp and maximum torque of 2586 Newton meters. Weight 1838 kg , the power weight ratio.

Cummins PT fuel system patented technology , high injection pressure , ensure that the engine good atomization , combustion. Efficient Holset turbocharger exhaust intake ensures more fully , improve engine efficiency and further improve combustion and reduce engine specific fuel consumption. Air Cooling technology to ensure intake fuller , better fuel economy .

Replaceable wet cylinder liners, cooling effect , easy to replace. All models parts versatility , high degree of serialization , and easy maintenance. Block and head are taking a built-in pressure lubricants Road , compact , low failure rate .

Cylinder block: made of high-strength alloy cast iron, with good rigidity, low vibration and low noise.

Camshaft: The single camshaft design can accurately control the valve and injection timing, and the optimized cam profile can reduce the impact force and improve the reliability and durability.

Crankshaft: The integral crankshaft is made of high-strength forged steel. The induction hardening process of fillet and journal can ensure higher fatigue strength of the crankshaft.

Piston: Using the latest aluminum alloy casting technology, the design of ω-shaped head and barrel-shaped skirt can compensate for thermal expansion and contraction to ensure a good fit.

Lubrication system: all moving parts are forced to lubricate; the large-capacity gear pump provides pressure lubricating oil to lubricate the bearings and cool the piston; the oil cooler, full-flow filter, and bypass filter maintain good oil condition.

Fuel system: Cummins PT fuel system, optimized combustion, surging power; STC distributed timing system to ensure better combustion in all working conditions; low-pressure fuel supply system, equipped with fuel one-way circuit, safe and reliable.

Cooling system: Forced water cooling with geared centrifugal water pump, large flow channel design, good cooling effect; spin-on water filter and special DCA additives can effectively prevent corrosion and cavitation, control the acidity of the coolant and remove impurities.

Intake and exhaust system: efficient Holset exhaust gas supercharger to further improve combustion; pressure pulse exhaust pipe can make full use of exhaust gas energy and improve engine efficiency.

Wide range of applications: Since Cummins entered China in 1975, K19 series engines have been widely used in construction machinery, heavy-duty vehicles, power generation, ship power and other fields; forming strategic partnerships with important customers.

High reputation: As one of the main models of the Cummins family, K19 series engines have won high recognition from customers in various fields with strong power, ultra-low fuel consumption, high reliability and low maintenance costs.

Air-to-air cooling, slow start and other technologies have further improved the engine's reliability, power, fuel economy, and emissions. The QSK19 engine launched in 2008 uses electronic injection technology with a power of 369-669kW.